Procter & Gamble Euskirchen

Procter & Gamble (P&G) is a global company with a large portfolio of well-known FMCG brands. Previously Ancra Systems already supplied truck un/loading solutions at other P&G locations. At this time the systems were introduced to enable an efficient shuttle transport between the Euskirchen (Germany) DC (Distribution Centre) and the new build CC (Customisation Centre) operated by Dönne + Hellwig Logistics.

The DC is equipped with a chain conveyor dock system, automatically loading the trailers shuttling between the DC and the 10,000 square metres CC. At the CC the EURO pallets are received using the dedicated chain conveyor unloading system operating at a speed of 0,1 m/s. Products then are gift set packed and sent back to the DC using a second chain conveyor dock system. Both docks are fitted with fork-lift truck stops. Prior to trailer loading, the complete load is verified by an outline checking device, preventing cargo and truck damage.

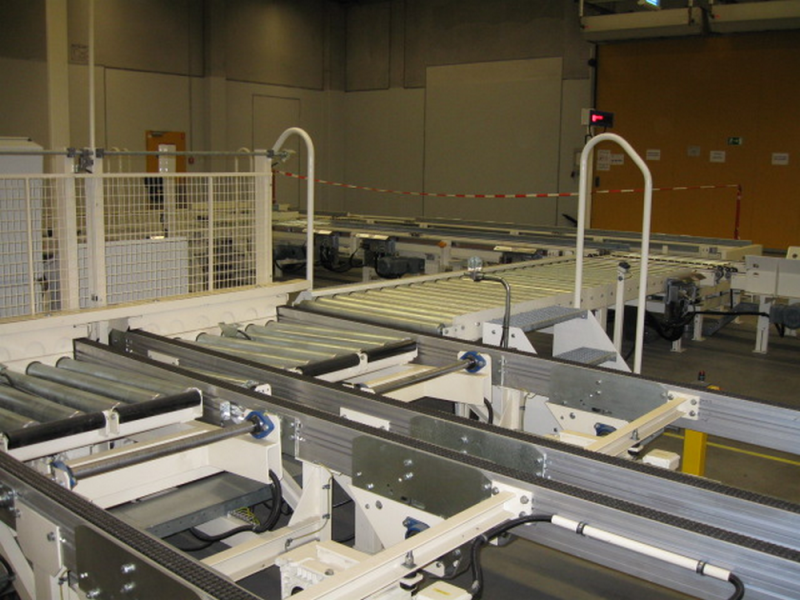

At the DC the loading and unloading systems are connected to the automated material handling system of the high bay storage, using two 90° transfer units. The trailers are equipped with a chain conveyor system and pneumatic shutter door which makes personnel interaction almost nil. With this configuration Ancra Systems again proved its capabilities in being able to deliver an excellent solution for optimal supply chain efficiency to Procter & Gamble.

(Please note that loading the factsheet can take several seconds.) Download factsheet